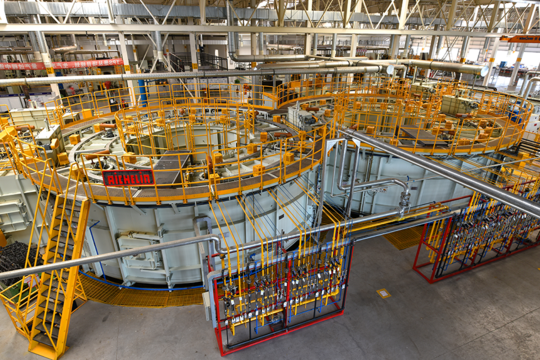

The ring hearth furnace is self-developed by AICHELIN. It combines the advantages of a rotary hearth furnace and a pusher furnace. The design allows a separation of heating, carburizing and diffusion zone so that different carbon levels and temperature profiles can be processed nearly independently in the different chambers. It is especially suitable for the press quenching and quenching heat treatment processes of bevel gears, driving gear shafts and other parts in the automobile industry.

The control system continuously combines the current informatization and industrialization. In addition to have basic modules such as automatic generation of control processes, automatic recording of process parameters, and realization of product tracking and traceability, its expansion modules add energy consumption statistic and analysis, mobile host computer monitoring system, realize the interface with the workshop MES system, and etc.

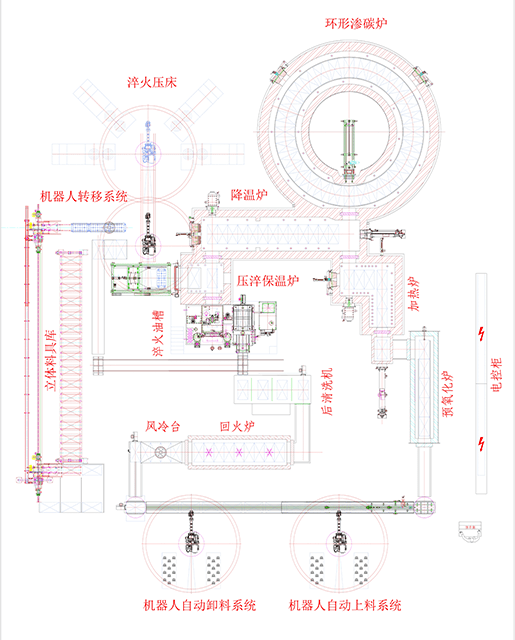

Typical Layout of Ring Heath Furnace with Press Quenching