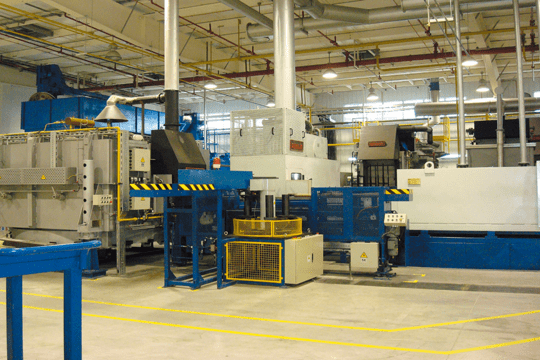

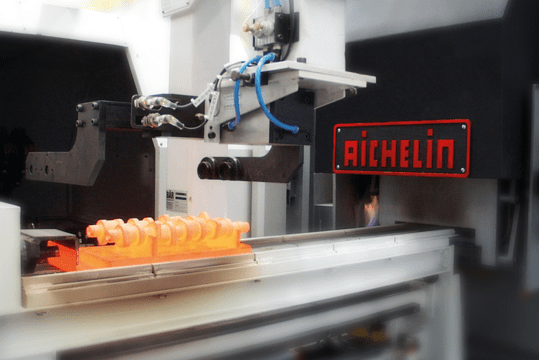

AICHELIN rotary hearth furnace is used for heating and quenching of spiral bevel gears, synchronizer gear sleeves, bearings and other parts in a large-scale protective atmosphere. Due to small space taken up, high continuous production capacity, one furnace door for loading and discharging, and the multi-layer traying is used to realize gas carburization, carbonitriding, clutch diaphragm hardening and bearing rings as well as other components Bainite isothermal quenching.

The control system continuously combines the current informatization and industrialization. In addition to have basic modules such as automatic generation of control processes, automatic recording of process parameters, and realization of product tracking and traceability, its expansion modules add energy consumption statistic and analysis, mobile host computer monitoring system, realize the interface with the workshop MES system, and etc.

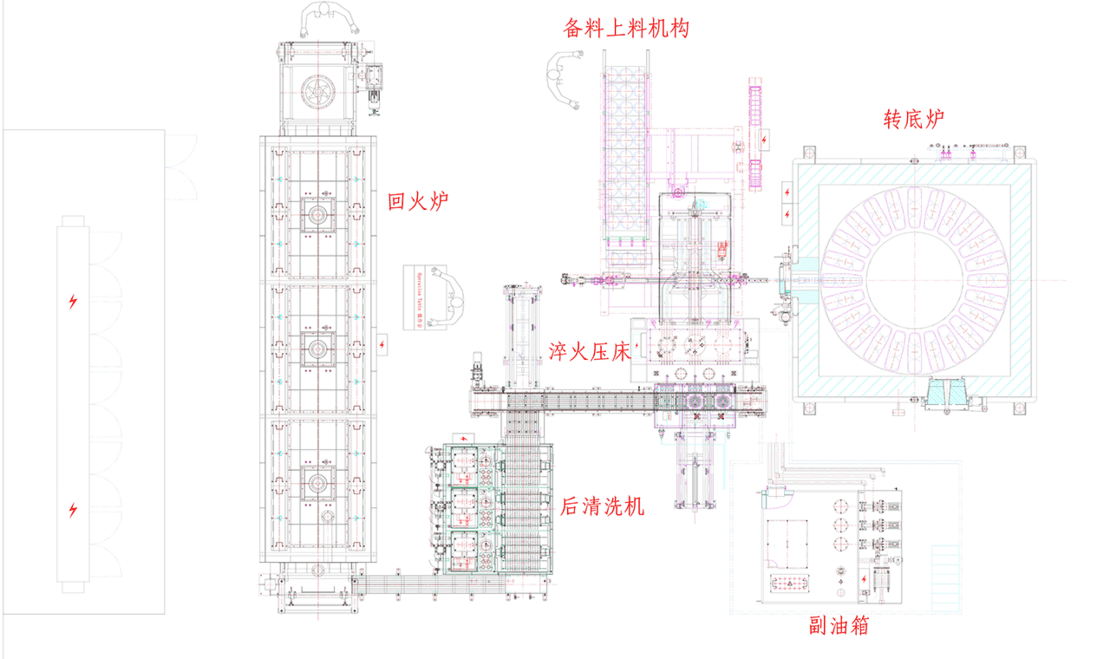

Layout of Rotary Hearth Furnace with Press Quenching